The LMR battery technology promises to transform the EV landscape by addressing three critical challenges: safety, energy density, and cost. Engineered to match the safety performance of Lithium Iron Phosphate (LFP) batteries, LMR also exceeds high-nickel batteries in energy density, potentially increasing vehicle range significantly. Additionally, Ford is targeting production costs that are substantially lower than those of mid-nickel batteries—an essential factor in achieving cost parity with traditional gasoline-powered vehicles.

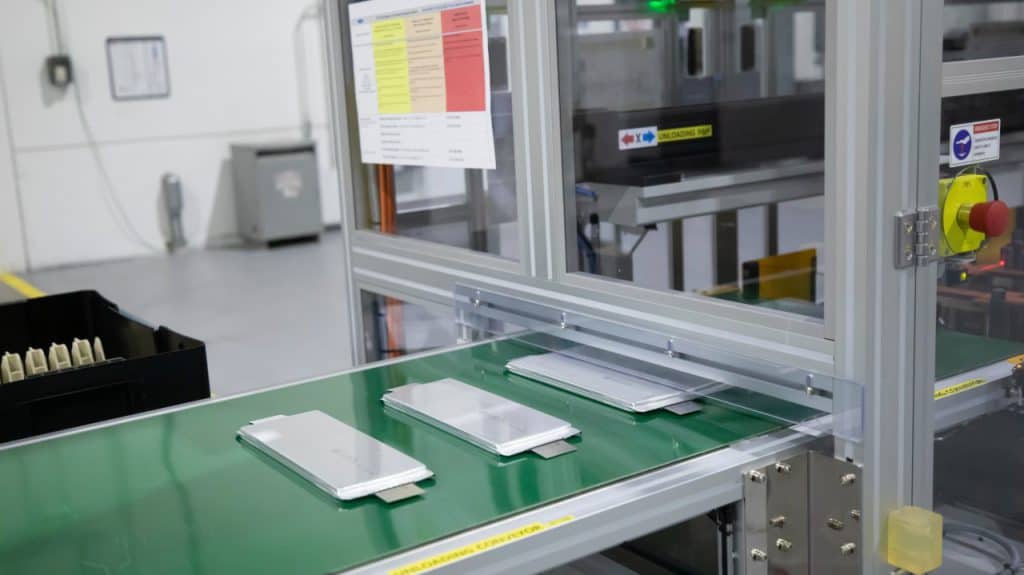

Ford is already producing second-generation LMR cells on its pilot line and is working to scale the technology for integration into its future vehicle lineup. The development marks the next phase in Ford’s battery evolution, following the implementation of nickel cobalt manganese (NCM) and LFP batteries in previous years.

The innovation is a direct result of the collaborative efforts of more than 135 leading chemists, scientists, and engineers at Ion Park. This cross-disciplinary team, drawn from top-tier research institutions and battery firms worldwide, operates in a cutting-edge environment designed to accelerate breakthroughs in battery materials science, cell design, and manufacturing processes.

Ford views the LMR technology as a crucial enabler for delivering EVs that are not only efficient and desirable but also accessible to a broader range of consumers. With this advancement, the automaker reaffirms its commitment to electrification and to democratizing electric mobility.